| 1 |

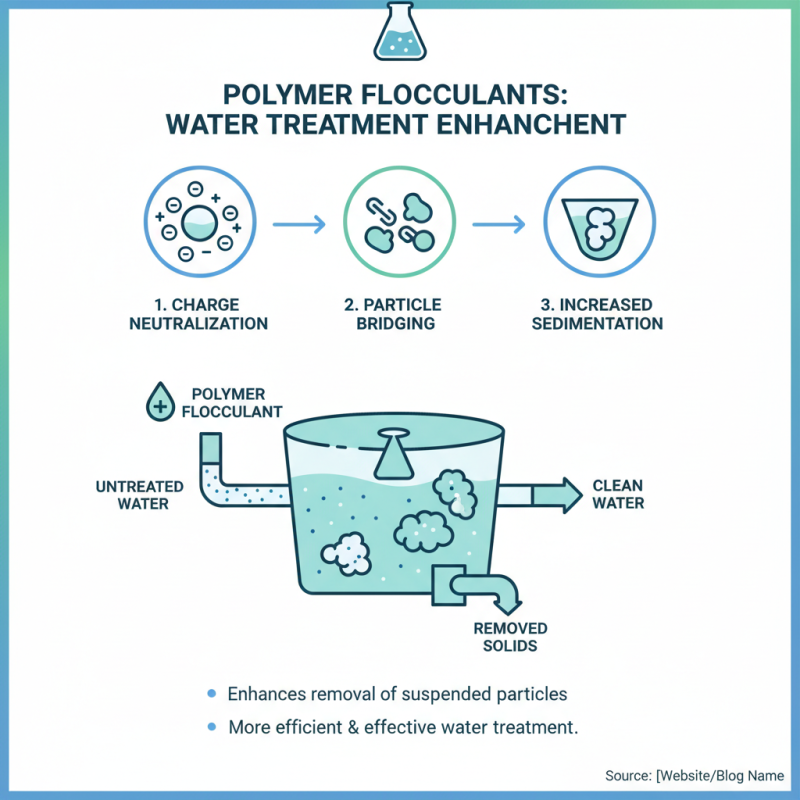

Determine the appropriate polymer type for your water chemistry. |

5 - 15 |

Jar testing before full-scale application. |

| 2 |

Adjust the pH levels for better coagulation. |

10 - 20 |

Continuous mixing during the addition. |

| 3 |

Start with a lower dosage and gradually increase. |

3 - 12 |

Careful monitoring of floc formation. |

| 4 |

Ensure proper mixing time for effective flocculation. |

15 - 25 |

Use dynamic mixers for optimal results. |

| 5 |

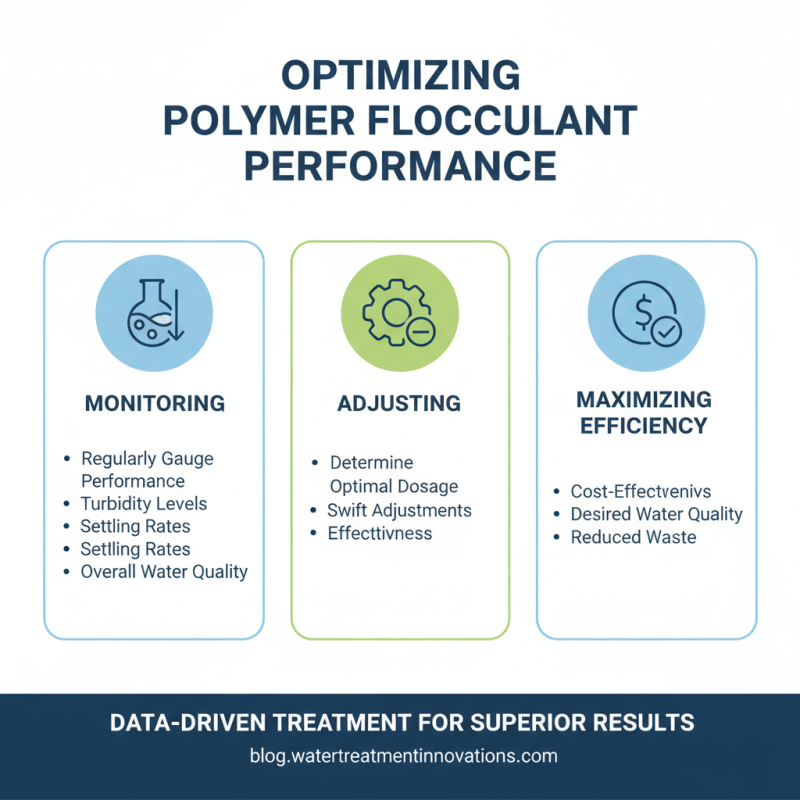

Monitor the turbidity levels after treatment. |

5 - 15 |

Adjust dosage based on turbidity readings. |

| 6 |

Use a flocculation aid to enhance performance. |

6 - 18 |

Combined with polymer flocculants. |

| 7 |

Test for optimal shear rates for floc breakage. |

8 - 16 |

Controlled flocculation conditions. |

| 8 |

Conduct regular maintenance of equipment. |

N/A |

Ensure mixers and tanks are clean. |

| 9 |

Evaluate post-treatment water quality frequently. |

5 - 14 |

Use online monitoring tools. |

| 10 |

Train staff regularly on flocculation techniques. |

N/A |

Hands-on training sessions. |