How to Use Polymer Acrylamide Effectively in Water Treatment Processes

In the realm of water treatment, the effective application of Polymer Acrylamide has become increasingly essential for achieving optimal results in various processes. As noted by Dr. Emily Morrison, a leading expert in polymer chemistry, "The strategic use of Polymer Acrylamide not only enhances the efficiency of water treatment but also plays a critical role in improving the overall quality of treated water." Her insights underscore the importance of understanding how to harness this powerful agent to address the complex challenges faced in water purification.

Polymer Acrylamide functions as a flocculant, aiding in the aggregation of suspended particles, thus facilitating their removal from water. This process is vital in ensuring that contaminants are adequately addressed, thereby yielding cleaner and safer water for consumption and industrial use. As water quality regulations become increasingly stringent, the demand for advanced solutions like Polymer Acrylamide has surged, pushing industries to explore its capabilities in depth.

In the following sections, we will delve into the various ways Polymer Acrylamide can be effectively utilized in water treatment processes. By examining its mechanisms, benefits, and best practices, we will provide a comprehensive guide for practitioners looking to enhance their water treatment strategies using this versatile polymer.

Understanding Polymer Acrylamide and Its Role in Water Treatment

Polymer acrylamide is a versatile chemical widely utilized in water treatment processes due to its effective flocculating properties. As a water-soluble polymer, it helps in the aggregation of suspended particles in wastewater, facilitating their removal from various water sources. When introduced to contaminated water, polymer acrylamide interacts with particulate matter, leading to the formation of larger aggregates or flocs. These flocs can then be easily separated through sedimentation or filtration, resulting in cleaner water.

The role of polymer acrylamide in water treatment extends beyond mere particle removal. It also enhances the efficiency of various treatment methods, including activated sludge processes and lagoon systems. By optimizing the settling characteristics of sludge and improving overall system performance, polymer acrylamide contributes to reduced operational costs and improved water quality. Furthermore, its application is not limited to municipal wastewater treatment; it is also effective in industrial applications, such as mining and food processing, where it aids in managing and recycling water resources. Its ability to facilitate faster and more effective treatment processes makes polymer acrylamide a valuable asset in achieving sustainable water management solutions.

Key Properties of Polymer Acrylamide for Effective Water Purification

Polymer acrylamide has emerged as a valuable agent in water treatment processes, primarily due to its exceptional ability to enhance the efficiency of water purification. One of its key properties is its high molecular weight, which allows it to form a gel-like structure that effectively traps contaminants, making it an ideal choice for flocculation and sedimentation processes. Moreover, its amphoteric nature enables it to interact with various charged particles in water, facilitating the removal of organic and inorganic impurities.

When using polymer acrylamide for water treatment, it is crucial to consider its dosage to achieve optimal results. An excessive amount may lead to inefficient floc formation, while too little may not adequately bound impurities. Conducting jar tests can provide a practical way to determine the appropriate dosage for specific water conditions.

**Tips**: Always ensure proper mixing to activate the polymer efficiently. Gradual addition while stirring can help achieve uniform distribution. Additionally, monitor pH levels regularly, as adjustments may enhance the performance of polymer acrylamide in purifying water. With its multifunctional characteristics, polymer acrylamide remains a cornerstone in modern water treatment processes.

Step-by-Step Application of Polymer Acrylamide in Treatment Processes

The application of polymer acrylamide in water treatment is a nuanced process that requires careful execution to maximize its efficiency. To begin with, it is essential to prepare the polymer solution properly. Dissolving the required amount of acrylamide in water should be done in a mixing tank, allowing sufficient time for uniformity. The concentration of the polymer is crucial, as it directly affects the flocculation and sedimentation processes. Typically, a concentration range of 0.1% to 0.5% is effective for various types of water treatment.

Once the polymer solution is ready, the next step is to introduce it into the wastewater treatment system. This is often done using a dosing pump, ensuring a steady and controlled release into the influent stream. The timing of polymer injection is vital; it should occur before the primary sedimentation phase to facilitate the agglomeration of suspended solids. Gently mixing the water and polymer is important to ensure that the flocculation occurs evenly. After allowing sufficient mixing time, the newly formed flocs will enhance the sedimentation process, leading to clearer effluent and cleaner water output. Monitoring the system closely during this stage will help in making real-time adjustments to the polymer dosage as needed, ensuring optimal treatment efficiency.

Polymer Acrylamide Usage in Water Treatment Processes

This chart illustrates the effectiveness of Polymer Acrylamide in different water treatment processes, showcasing the reduction in Total Suspended Solids (TSS) over time.

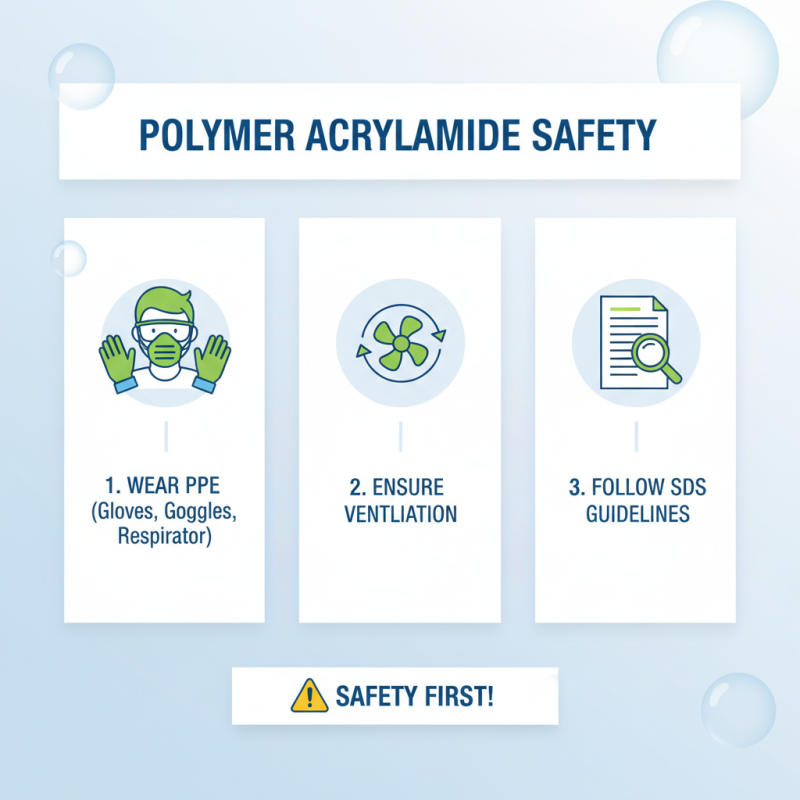

Safety Considerations When Using Polymer Acrylamide in Water Treatment

When utilizing polymer acrylamide in water treatment processes, safety considerations are paramount. Polymer acrylamide can pose certain health risks, primarily through inhalation or skin contact. Therefore, it is crucial to ensure that all operators are equipped with appropriate personal protective equipment (PPE), including gloves, goggles, and respiratory protection. Furthermore, adequate ventilation should be maintained in work areas to minimize exposure to airborne particles. Implementing safety data sheets (SDS) provides clear guidelines on handling, storage, and emergency measures.

In addition to personal safety measures, proper storage and disposal of polymer acrylamide are essential to prevent environmental contamination. The substance should be stored in a cool, dry place away from incompatible materials. Furthermore, any waste or spills should be managed according to local regulations to mitigate any potential hazards. Regular training sessions for personnel on the safe handling of chemicals and emergency response protocols can enhance safety practices and ensure that everyone is aware of the necessary precautions when working with polymer acrylamide in water treatment settings.

Evaluating the Effectiveness of Polymer Acrylamide in Water Treatment Systems

Polymer acrylamide has emerged as a pivotal agent in enhancing water treatment processes, particularly in the removal of suspended solids and organic materials. According to a study published by the American Society of Civil Engineers, the efficacy of polymer acrylamide in coagulation and flocculation can improve sedimentation rates by up to 50%, thereby significantly reducing the volume of sludge generated during treatment. This is particularly advantageous in municipal wastewater treatment facilities where space and operational efficiency are critical.

Furthermore, research highlighted in the Journal of Environmental Engineering indicates that adjusting the molecular weight of the acrylamide polymer can optimize its performance across various applications. Low molecular weight polymers tend to enhance the settling of smaller particles, while high molecular weight variants are more effective in forming larger flocs. A comparison of various studies shows that using polymer acrylamide can lead to a reduction in turbidity levels by more than 90%, making it a highly effective solution for improving water clarity and quality in both industrial and municipal settings. These findings underscore the importance of evaluating polymer properties to maximize their effectiveness in diverse water treatment systems.

How to Use Polymer Acrylamide Effectively in Water Treatment Processes

| Parameter |

Value |

Unit |

| Polymer Concentration |

0.1 - 1.0 |

% (w/v) |

| Optimal pH Range |

6 - 8 |

pH Units |

| Mixing Time |

15 - 30 |

minutes |

| Settling Time |

30 - 60 |

minutes |

| Removal Efficiency |

75 - 95 |

% (%) |

| Application Areas |

Municipal, Industrial |

N/A |