The Ultimate Guide to Liquid Dosing Pumps in 2025 Top Applications and Trends

In recent years, the market for Liquid Dosing Pumps has seen significant advancements, driven by the increasing demand for precise fluid handling across various industries. According to a report by Research and Markets, the global liquid dosing pump market is projected to reach $3.5 billion by 2025, growing at a CAGR of 5.2%. This growth is indicative of a rising awareness regarding efficiency, accuracy, and the environmental impact of chemical handling processes.

Industry experts have emphasized the importance of innovation in this field. Dr. Emily Tran, a leading expert in fluid dynamics and dosing technology, noted, "The evolution of Liquid Dosing Pumps is critical for industries that rely on precision and reliability, especially in sectors such as pharmaceuticals and water treatment." As applications expand and technology evolves, we can expect to see an increased focus on automation, smart technology integration, and energy efficiency, which will further influence the trends in liquid dosing solutions.

This guide delves into the top applications and emerging trends in the Liquid Dosing Pump sector for 2025, aiming to provide insights that will help professionals navigate this evolving landscape and make informed decisions for their operational needs.

Understanding Liquid Dosing Pumps: Basics and Mechanisms Explained

Liquid dosing pumps are essential devices widely used in various industries for precise fluid measurement and delivery. Understanding the basic principles and mechanisms of these pumps is vital for optimizing their application in processes ranging from water treatment to pharmaceutical production. According to a report by MarketsandMarkets, the global liquid dosing pump market is projected to reach USD 5.9 billion by 2025, indicating a significant increase in demand and innovation in this field.

The primary mechanism of liquid dosing pumps involves creating a specific flow rate through the use of positive displacement or centrifugal forces. Positive displacement pumps are commonly favored for their accuracy in delivering fixed volumes of liquid, making them ideal for applications requiring stringent dosing precision. In contrast, centrifugal pumps are preferred in scenarios where larger volumes need to be moved quickly, albeit with slightly less precision. The growth of the food and beverage industry, which increasingly requires automated solutions for both efficiency and compliance, is driving advancements in these technologies, as detailed in a recent report by Technavio.

As we look toward 2025, trends indicate a transformative shift towards smart and IoT-enabled liquid dosing pumps. These pumps are designed to communicate real-time data regarding flow rates, pressures, and operational statuses, thus enabling better monitoring and control. The incorporation of advanced sensors and automation technologies will not only enhance operational efficiency but also contribute to waste reduction. This shift towards smarter systems is forecasted to be a pivotal aspect of industry development, addressing both economic and environmental responsibilities.

Key Applications of Liquid Dosing Pumps in Various Industries

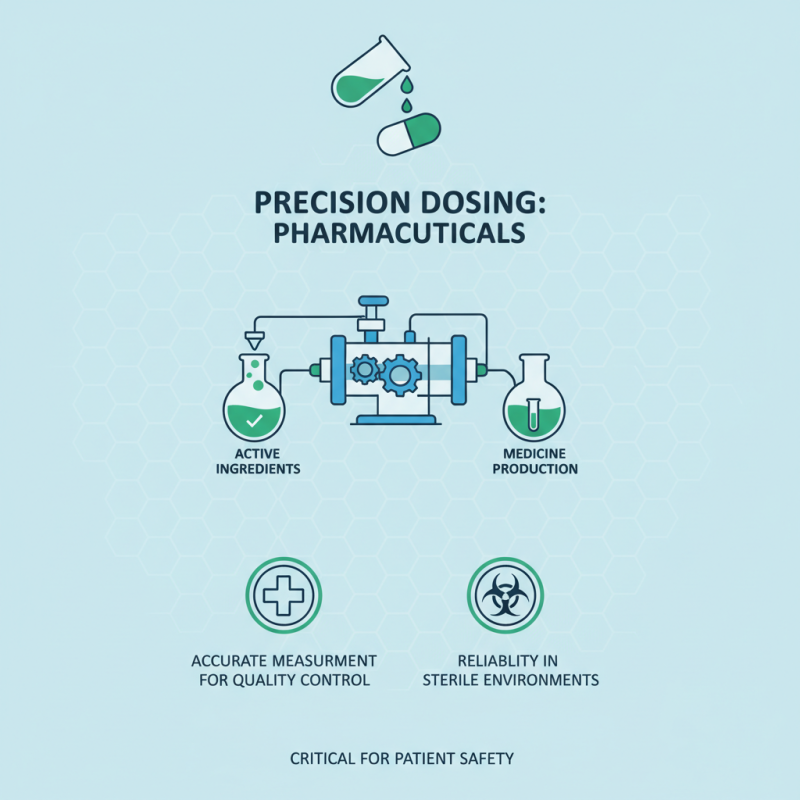

Liquid dosing pumps are essential across a diverse range of industries, serving critical functions in processes that require precise liquid measurement and transfer. In the pharmaceutical sector, these pumps ensure accurate dosing of active ingredients, which is vital for maintaining product quality and efficacy. Their reliability in sterile environments allows for the consistent production of medicines, where any deviation can result in significant consequences for patient safety.

In the chemical and food processing industries, liquid dosing pumps are utilized for mixing and blending various substances. These pumps facilitate the controlled introduction of additives, flavorings, or preservatives, ensuring the integrity and safety of the final product. Furthermore, with the increasing emphasis on sustainability, many manufacturers are adopting advanced liquid dosing systems that minimize waste and enhance efficiency, allowing for a more environmentally friendly approach to production. As technology evolves, the integration of smart features in these pumps is becoming prevalent, enabling real-time monitoring and data analysis for optimized performance across various applications.

Emerging Trends in Liquid Dosing Pump Technology for 2025

In 2025, the landscape of liquid dosing pump technology is set to be transformed by several emerging trends that promise to enhance efficiency and precision across various industries. One significant trend is the integration of smart technologies, such as IoT connectivity, which allows for real-time monitoring and data analytics. This enables operators to gain deeper insights into the performance of their dosing pumps, optimizing operations and reducing downtimes.

Moreover, advancements in materials and design are leading to pumps that are not only more durable but also capable of handling a wider range of liquids, including those with aggressive chemicals. This evolution is critical for industries such as pharmaceuticals and chemicals, where product integrity and consistent dosing are paramount.

**Tips**: When selecting a liquid dosing pump, consider models that offer digital features for enhanced control and monitoring. Always evaluate the materials used in the pump's construction to ensure compatibility with the liquids being handled. Finally, look for systems that allow easy integration with existing processes to avoid extensive overhauls in your operations.

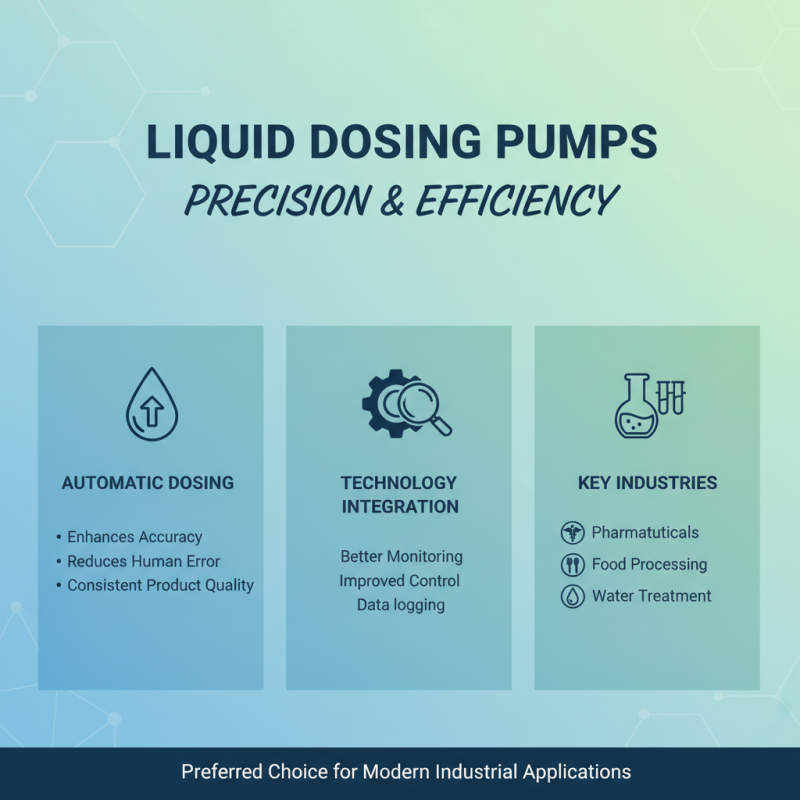

Advantages of Using Liquid Dosing Pumps Over Traditional Methods

Liquid dosing pumps have emerged as a preferred choice in various industries due to their precision and efficiency. Unlike traditional manual methods of liquid measurement, these pumps offer automatic dosing solutions that enhance accuracy and reduce human error. This is particularly significant in settings such as pharmaceuticals, food processing, and water treatment, where the exact amount of liquid can drastically influence product quality and consistency. The integration of technology in liquid dosing systems also facilitates better monitoring and control, which is often lacking in conventional methods.

Tips: When selecting a liquid dosing pump, consider the specific requirements of your application, including the type of liquid being pumped, flow rate, and required accuracy. Additionally, ensure that the pump materials are compatible with the liquids to prevent contamination and wear. Regular maintenance checks can also help in extending the lifespan of the pump and maintaining optimal performance.

Another advantage of liquid dosing pumps is their ability to handle a variety of liquids, including corrosive and viscous substances. This versatility is a significant improvement over traditional methods, which may be limited to certain types of fluids. Moreover, with advancements in technology, some dosing pumps are now equipped with smart features that allow real-time data collection and remote operation, leading to even greater efficiency and integration into automated systems.

Tips: Always evaluate the energy requirements and overall efficiency of the pump to ensure cost-effective operation. Investing in systems with energy-saving features can lead to long-term savings and a reduced environmental impact.

Future Challenges and Considerations for Liquid Dosing Pump Adoption

As industries increasingly adopt liquid dosing pumps, several challenges and considerations are emerging that impact their integration and efficiency. According to a report by the Global Liquid Dosing Pumps Market, the sector is projected to grow at a CAGR of 4.5% from 2023 to 2028, driven by the rising demand in sectors such as pharmaceuticals, food and beverage, and chemical processing. However, the adoption of these pumps is not without its hurdles. One prominent challenge is the necessity for ongoing maintenance and reliability management. Companies must invest in training for their personnel to ensure optimal performance and minimize downtime, as failing to do so can lead to significant financial losses.

Another consideration is the increasing push for sustainability within manufacturing practices. Liquid dosing pump technologies are evolving to become more energy-efficient and environmentally friendly, with innovations aimed at reducing waste and energy consumption. According to a study from the International Society for Automation, energy-saving technologies in liquid dosing pumps can reduce operational costs by up to 30%. As businesses seek to lower their carbon footprints, selecting pumps that adhere to stringent regulatory standards will be crucial. Moreover, the transition towards Industry 4.0 necessitates that manufacturers assess the integration of smart technologies into dosing systems, ensuring they are equipped not only for current demands but also for future advancements and sustainability goals.