Essential Tips for Choosing the Right Anionic Flocculant for Your Projects

When embarking on projects that require water treatment processes, selecting the appropriate flocculant is crucial for achieving optimal results. Among the various types available, Flocculant Anionic stands out due to its effectiveness in promoting the aggregation of suspended particles, leading to improved sedimentation rates and enhanced clarity of water. By understanding the unique characteristics of anionic flocculants, project managers and environmental engineers can make informed decisions that contribute to the success and sustainability of their operations.

The choice of a Flocculant Anionic can significantly influence the overall efficiency and cost-effectiveness of a project. Various factors must be considered, including the specific characteristics of the wastewater being treated, the desired outcome, and the operational conditions. By gaining insight into the compatibility of anionic flocculants with different materials and their behavior under various pH and ionic strength conditions, professionals in the field can tailor their approach to meet the demands of their unique projects.

This guide aims to provide essential tips for identifying and selecting the right Flocculant Anionic for your needs. By considering the key aspects outlined herein, you can ensure that your choice leads to effective water treatment solutions that are not only efficient but also environmentally responsible.

Understanding Anionic Flocculants and Their Applications

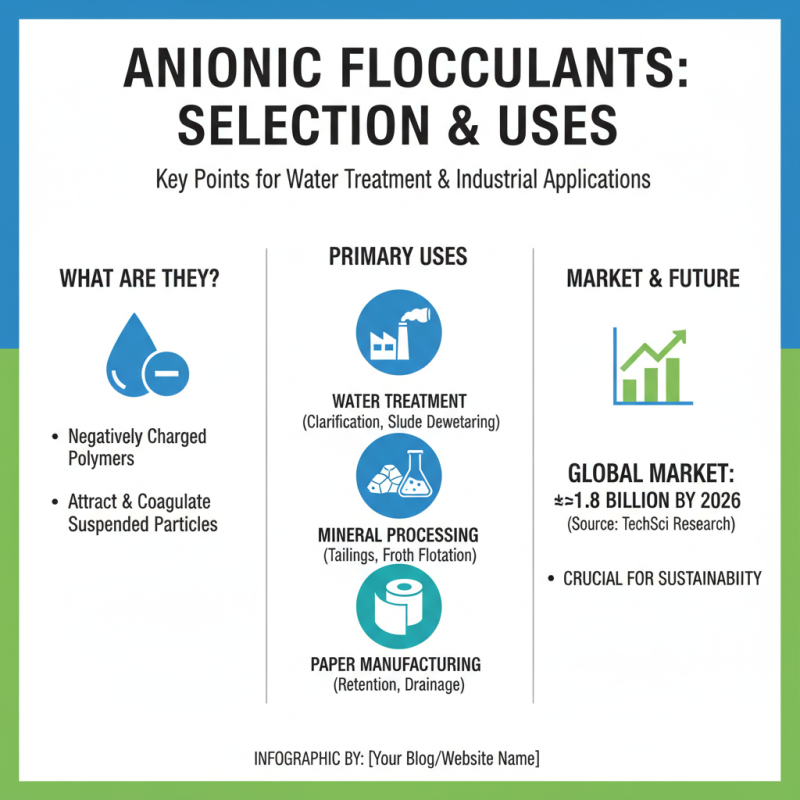

Anionic flocculants are essential agents used to promote the aggregation of particles in various industrial processes, particularly in wastewater treatment, mining, and paper production. These synthetic polymers carry a negative charge, allowing them to interact effectively with positively charged particles, resulting in the formation of larger clumps or flocs. This aggregation enhances sedimentation and separation, making the treatment process more efficient. Understanding the specific applications of anionic flocculants is crucial for selecting the appropriate type for your project, as each application may require different molecular weights and charge densities to achieve optimal performance.

When choosing the right anionic flocculant, consider the specific characteristics of your application. One essential tip is to evaluate the properties of the material being treated, such as particle size and charge, to ensure compatibility with the flocculant. Additionally, it's beneficial to conduct jar tests under various conditions to determine the most effective dosage and flocculant type. Ensure to also analyze the water chemistry, including pH levels and ionic strength, as these factors can significantly influence the flocculation process. By following these guidelines, you can optimize your selection and enhance the efficiency of your projects.

Essential Tips for Choosing the Right Anionic Flocculant for Your Projects

Key Factors to Consider When Selecting Anionic Flocculants

When selecting the right anionic flocculant for your projects, several key factors come into play. First and foremost, understanding the specific application and requirements of your project is crucial. Factors such as the type of materials being treated, the desired outcome, and environmental conditions can significantly influence the choice of flocculant. For instance, the molecular weight of the flocculant can affect its efficiency; higher molecular weight flocculants generally provide better sedimentation and clarification results.

Another important consideration is the charge density of the flocculant. Anionic flocculants with varying charge densities may perform differently depending on the characteristics of the particulate matter present in the water. It’s essential to match the anionic charge to the nature of the substances being flocculated to achieve optimal performance. Additionally, evaluating the flocculant's compatibility with other chemicals in the treatment process is vital to avoid potential interactions that could diminish its effectiveness. By thoroughly assessing these factors, you can select the most suitable anionic flocculant that aligns with your project goals.

Essential Tips for Choosing the Right Anionic Flocculant for Your Projects - Key Factors to Consider When Selecting Anionic Flocculants

| Factor |

Description |

Typical Applications |

Dosage Recommendations |

| Molecular Weight |

Determines the flocculant's ability to bind with particles. |

Wastewater treatment, mining. |

1-5 mg/L depending on application. |

| Charge Density |

Influences the interaction with particles and effectiveness. |

Sludge thickening, potable water treatment. |

2-10 mg/L, varies by process. |

| pH Compatibility |

Performance can vary significantly with pH levels. |

Industrial effluent treatment. |

Adjust according to pH readings. |

| Temperature Stability |

Ability to perform in varying temperatures. |

Coal washery, petrochemical industry. |

1-3 mg/L, depending on heat sensitivity. |

| Environmental Impact |

Consider biodegradability and toxicity. |

Agricultural run-off management. |

Monitor for ecological effects. |

Types of Anionic Flocculants and Their Performance Characteristics

When selecting an anionic flocculant for various projects, understanding the different types available and their performance characteristics is crucial. Anionic flocculants, which carry a negative charge, are widely used in various industries, particularly in water treatment, mineral processing, and paper manufacturing. According to a report by TechSci Research, the global anionic flocculants market is projected to reach approximately $1.8 billion by 2026, illustrating their significant role in industrial applications.

There are several categories of anionic flocculants, including polyacrylamide-based flocculants, which are favored for their high efficacy in sedimentation processes. The performance of anionic flocculants can be influenced by factors such as molecular weight and charge density. For example, lower molecular weight flocculants typically perform well in high shear conditions, while those with higher molecular weights are effective in settling and dewatering processes. According to a study published in the Journal of Environmental Management, optimal flocculant choice can enhance settling velocities by up to 50%, emphasizing the importance of selecting the right type for specific applications.

Moreover, the chemical structure and degree of hydrolysis can impact the flocculant's effectiveness. Research indicates that anionic flocculants with a higher degree of hydrolysis tend to perform better in environments with low turbidity, while those with lower hydrolysis levels excel in high-turbidity scenarios. This nuanced understanding of anionic flocculants' performance characteristics is essential for engineers and project managers looking to optimize their processes and ensure efficient resource management.

Evaluating Effectiveness: Testing and Quality Assessment of Anionic Flocculants

When selecting an anionic flocculant for your projects, evaluating its effectiveness is crucial. The performance of these polymers can vary considerably based on their molecular weight, charge density, and overall formulation. To ensure you choose the right product, it’s essential to conduct systematic testing under the specific conditions your project entails. This might include varying the concentration of the flocculant, adjusting pH levels, and assessing the type of solids you are trying to remove. Such testing will provide insight into the flocculant's coagulation capabilities and settling characteristics.

Quality assessment of anionic flocculants can also be achieved through a series of standardized tests. Evaluate parameters such as turbidity reduction, sedimentation rate, and the clarity of the supernatant after the flocculation process. It's vital to monitor these outcomes consistently to determine the most effective dosage and application method. Additionally, consider conducting pilot-scale tests to simulate real-world conditions, which can offer a more comprehensive understanding of how the flocculant will perform in practice. Utilizing these approaches will help ensure the selection of an anionic flocculant that meets the specific needs of your application while delivering optimal results.

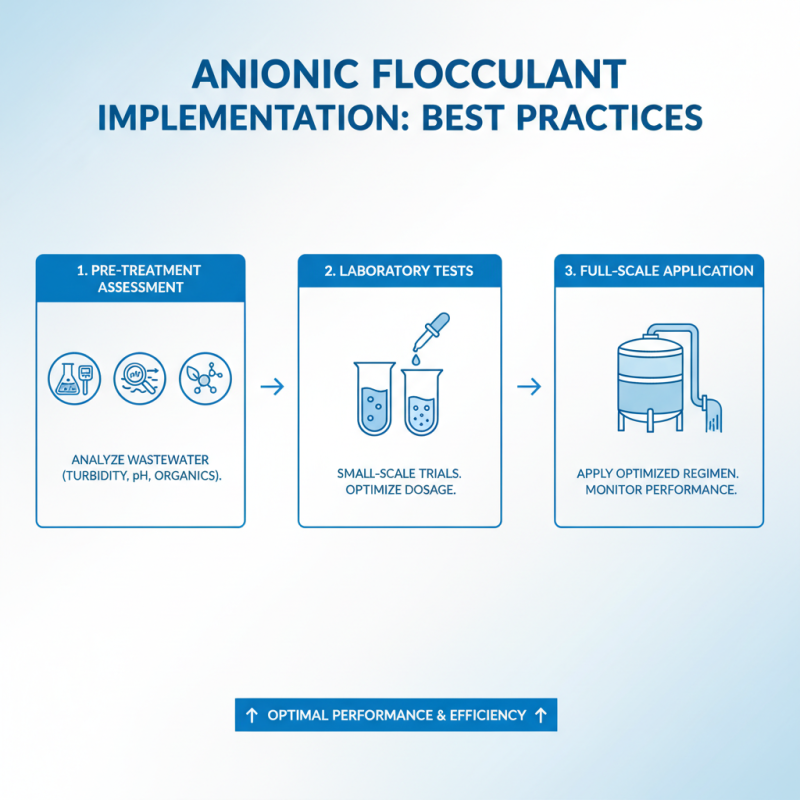

Best Practices for Implementing Anionic Flocculants in Projects

When implementing anionic flocculants in your projects, it is essential to adhere to best practices to ensure optimal performance and efficiency. First, conducting a thorough pre-treatment assessment is crucial. This involves analyzing the characteristics of the wastewater or slurry you aim to treat, such as its turbidity, pH, and organic matter content. These factors significantly influence the choice and dosage of the flocculant, as well as the required conditions for effective flocculation. Engaging in laboratory-scale tests prior to full-scale application can provide valuable insights and help fine-tune the dosing regimen to achieve the desired results.

Additionally, monitoring and adjusting operational parameters during the application process are vital for successful flocculation. This includes controlling mixing energy, retention time, and the sequence of chemical additions. Proper agitation ensures that the anionic flocculant uniformly interacts with suspended particles, promoting better agglomeration. Post-treatment processes should also be in place, as effective sedimentation or filtration following flocculation can enhance overall treatment efficiency. Regularly evaluating system performance and adjusting parameters based on real-time feedback can lead to improved outcomes and sustained effectiveness in your projects.