How to Choose the Right Color Fixing Agent for Your Textile Projects

In the dynamic world of textile production, selecting the appropriate Color Fixing Agent is critical to achieving vibrant and long-lasting colors. As expert in the field, Dr. Amelia Carter, a renowned color chemist, emphasizes the importance of this selection process by stating, "The right Color Fixing Agent can not only enhance the color quality but also significantly improve the durability of textiles." This insight highlights the vital role that color fixing agents play in the overall textile manufacturing process, influencing both aesthetic appeal and product longevity.

When embarking on a textile project, understanding the different types of Color Fixing Agents available is essential. They can vary widely in their chemical composition, application methods, and compatibility with different fabrics and dyes. This variability necessitates a careful evaluation of factors such as the type of dye used, the nature of the fabric, and the end-use requirements. By making informed choices, textile designers and manufacturers can not only ensure the success of their projects but also meet the evolving demands of consumers for high-quality, colorfast textiles.

As we delve deeper into the nuances of choosing the right Color Fixing Agent, it is vital to examine the key characteristics and performance metrics that can guide this decision. By equipping ourselves with the right knowledge and insights, we can elevate the quality of our textile products and satisfy the expectations of a discerning market.

Understanding the Role of Color Fixing Agents in Textiles

Color fixing agents play a crucial role in the textile industry, primarily by ensuring that dyes adhere firmly to the fibers of the fabric. These agents help prevent color bleeding and fading, which can compromise the integrity and aesthetic appeal of textile products. By forming a strong bond with dye molecules, color fixing agents enhance the durability of the colors throughout the fabric's lifespan. This is essential for maintaining the quality of textiles through multiple washes and everyday use.

Understanding the different types of color fixing agents is key to selecting the appropriate one for specific textile projects. Agents can vary based on the type of dye, fiber content, and the intended use of the final product. For instance, some agents work better with natural fibers, while others are designed for synthetic materials. Additionally, the application method—such as exhaustion or pad-dry techniques—can influence the efficacy of the color fixing process. As a result, thorough knowledge of the interaction between the colorants and the fixing agents is vital for achieving desirable results in textile coloration.

Different Types of Color Fixing Agents and Their Applications

Color fixing agents play a crucial role in ensuring the longevity and vibrancy of textile colors, making them an essential component in various textile projects. Generally, there are several types of color fixing agents, each with distinct properties and applications. For instance, cationic fixing agents are commonly used for natural fibers like cotton and wool. According to a report by the Textile Research Institute, around 30% of textile manufacturers rely on cationic agents due to their strong affinity for anionic dyes, facilitating improved colorfastness against washing and light exposure.

Moreover, nonionic fixing agents, which provide a neutral pH level, are particularly effective with synthetic fibers such as polyester and nylon. Industry insights reveal that their usage has grown by approximately 25% in recent years due to increased demand for eco-friendly textile finishing processes. They help enhance the stability of dyes, enabling manufacturers to achieve richer colors while minimizing environmental impact. Understanding the specific needs of your project and the characteristics of these agents can significantly influence the overall quality of the finished textile product. Selecting the right color fixing agent not only optimizes coloration but also contributes to sustainability practices in textile production.

Color Fixing Agent Types and Their Applications

Factors to Consider When Choosing a Color Fixing Agent

When selecting a color fixing agent for textile projects, it’s essential to consider several key factors that can influence the effectiveness of your dyeing process. One of the primary considerations is the type of fibers present in your textiles. Different fibers, such as cotton, wool, or synthetic materials, may react differently to specific color fixing agents. Ensuring compatibility between the agent and the fiber type not only enhances color retention but also prevents issues like fading or bleeding during washing and wear.

Another critical factor is the anticipated end-use of the fabric. For instance, textiles meant for outdoor applications may require a fixing agent with high resistance to light and environmental factors, while garments intended for everyday wear may prioritize comfort and washability. Additionally, examining the pH stability and temperature tolerance of the color fixing agent can help in maintaining the desired color integrity through various processes. Lastly, environmental considerations are increasingly important; opting for sustainable and non-toxic fixing agents aligns with eco-friendly practices, making them a preferable choice in today’s market.

Testing and Evaluating Color Fixing Agents for Effectiveness

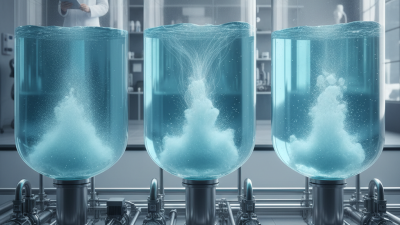

When selecting a color fixing agent for textile projects, testing and evaluating their effectiveness is crucial for ensuring the vibrancy and longevity of dye applications. Start by conducting small-scale trials with different color fixing agents to observe their performance under various conditions. It’s important to consider factors such as temperature, pH levels, and the type of fabric being treated, as these can significantly influence the fixation process. Make note of how well each agent enhances color retention and resist fading during washing and exposure to light.

To effectively evaluate the results, utilize standardized testing procedures that allow for a consistent comparison of colorfastness. For instance, after applying the color fixing agent and drying the textile, subject samples to wash fastness tests and light fastness assessments. Measure the color change and assess any alterations using tools like spectrophotometers or visual evaluation against grey scales. This systematic approach not only identifies the most suitable agent for your specific materials but also enhances the overall quality and durability of your textile products.

Best Practices for Using Color Fixing Agents in Textile Projects

When choosing color fixing agents for textile projects, it is crucial to understand the application methods and the specific requirements of the fabric being used. Best practices suggest a careful evaluation of the textile type; for instance, natural fibers like cotton and wool may require different fixing agents than synthetic fibers such as polyester. According to the "Textile Repair and Maintenance" report published by the Textile World Association, the effectiveness of color fixing agents is often measured by their ability to withstand washing and light exposure, with recommendations indicating that agents with a high retention rate (above 90%) should be prioritized for durable textiles.

In application, it is essential to follow the manufacturer’s guidelines for concentration levels and temperature during the fixing process. Studies have shown that improper concentrations can lead to either insufficient color fixing or excess, resulting in fabric stiffness. The International Journal of Textile Science cites that achieving an optimal pH level during application can enhance the effectiveness of the agents used, with a neutral pH of around 7 being most beneficial for a wide range of fabrics. Moreover, conducting a preliminary test on a small fabric swatch can help determine compatibility and effectiveness without risking the integrity of larger textile batches. Adhering to these best practices can significantly enhance color retention and overall quality in textile projects.